The significance of PVC Hoses must be acknowledged across diverse global sectors. These components fulfill critical functions in multiple industries by enabling dependable conveyance of fluids and materials. Applications span agriculture, industrial installations, chemical handling, and HVAC systems. Thus, grasping the basics of PVC hose construction and its variants is imperative.

PVC Hoses are renowned for their adaptability, cost-efficiency, and resilience against corrosion and wear. Constructed from a robust thermoplastic polymer, they facilitate the transfer of liquids, gases, and solids. The inherent attributes of PVC render it suitable for a broad array of uses. Compared to rubber alternatives, PVC Hoses offer reduced weight and lower costs. Consequently, PVC Hoses have supplanted rubber in numerous scenarios.

This article delivers a thorough examination of PVC flexible hoses and their industrial implementations. It addresses key selection criteria for matching hoses to particular operational demands. Readers gain foundational insights into PVC Hoses, including their benefits. Furthermore, distinctions between PVC and polyurethane hoses are outlined. Upon completion, professionals can evaluate options astutely, identifying specifications aligned with precise project needs.

What is A PVC Hoses

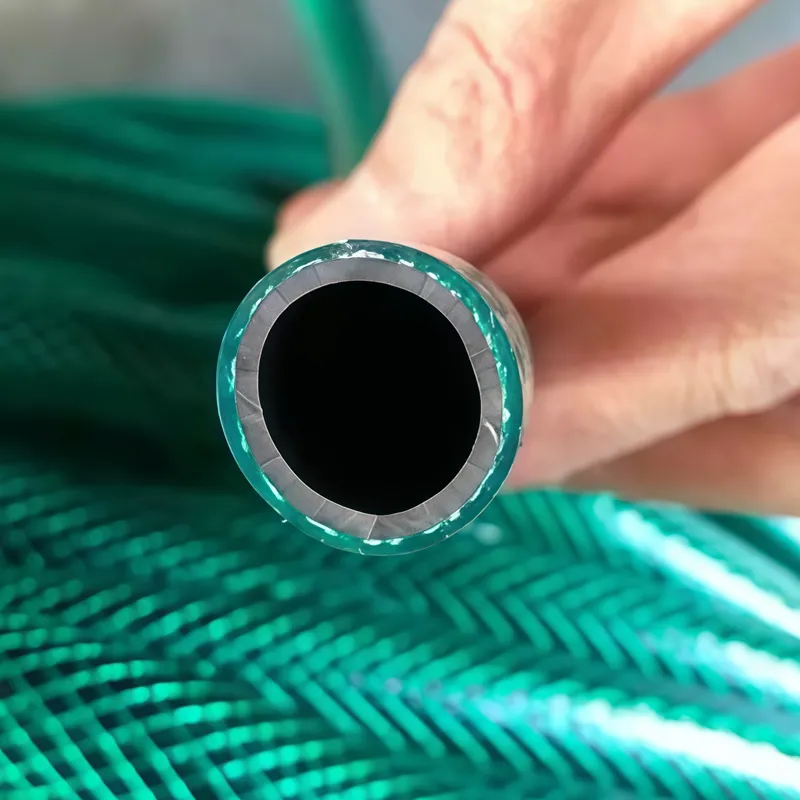

PVC hose refers to polyvinyl chloride hose. It constitutes a PVC flexible hose derived from a synthetic thermoplastic polymer. Such hoses excel in conveying fluids, gases, and solid materials across industrial settings. PVC hose assembly comprises several layers. The core inner layer consists of PVC, while reinforcement layers incorporate alternative materials.

This inner layer ensures unobstructed flow paths for media. Reinforcement layers, in contrast, enhance tensile strength and pressure tolerance. The exterior layer shields against environmental stressors, including abrasion and chemical exposure.

Fabrication of PVC hose entails four key stages:

- In the compounding phase, PVC resins are blended with plasticizers, stabilizers, and additives.

- Extrusion follows, where the mixture is heated to form a seamless tubular profile, then cooled to set and maintain dimensional stability.

- Reinforcement integration incorporates supportive layers via methods such as braiding, spiraling, or encircling the inner tube with materials.

- The sequence concludes with curing and final processing.

Advantages of PVC Hose

- PVC Hoses demonstrate superior flexibility. This trait simplifies manipulation, installation, and positional adjustments in operational contexts.

- They offer robust resistance to abrasion, impact, and rupture, promoting extended operational longevity under rigorous environments.

- PVC hose withstands exposure to numerous chemicals, rendering it appropriate for varied industrial processes.

- PVC flexible hose resists degradation from weathering, ultraviolet radiation, and ozone, establishing it as an optimal selection for exterior deployments.

- Relative to rubber hoses, it provides lighter weight and economic viability.

- Upkeep for PVC hose remains straightforward.

Variety of PVC Hoses And Their Applications

PVC hose variants are engineered to address distinct requirements and operational scenarios. Each variant delivers specialized attributes tailored to targeted functions. Below, PVC hose is classified into six principal categories, with analysis of their features, deployments, strengths, and constraints.

PVC Braided Hose

These PVC hoses integrate PVC with braided textile reinforcements, commonly utilizing premium synthetic fibers like polyester or nylon. PVC braided hoses see extensive adoption across sectors. They support plumbing, gardening, water distribution networks, and general industrial tasks.

Pros

- PVC braided hose accommodates diverse operational demands with high versatility.

- It achieves exceptional durability and extended service intervals.

- Braided reinforcement bolsters longevity and resilience.

- PVC braided hoses resist a range of chemicals effectively.

- It presents an economical alternative.

Cons

- PVC braided hose imposes temperature constraints, limiting suitability for extreme thermal conditions.

- Prolonged UV exposure risks deterioration of the external PVC surface.

- It proves inadequate for select chemical exposures.

PVC Layflat Hose

True to its designation, PVC layflat hose features a flattened, pliable PVC configuration. Its fabrication employs a specialized technique of extruding PVC into a planar form, followed by edge folding and securing. PVC layflat hose serves broad industrial roles. In agriculture, it underpins effective irrigation networks. It also excels in dewatering tasks, such as evacuating surplus water from inundated or subsurface zones.

Pros

- PVC layflat hose facilitates space-efficient storage and simplified transport.

- Its low weight eases handling and positioning, allowing swift connection to fluid sources and reducing deployment time.

- PVC layflat hoses provide outstanding flexibility for obstacle navigation and installation.

- It delivers cost efficiency.

Cons

- PVC layflat hoses lack compatibility with elevated pressure or temperature regimes.

- It remains prone to wear from friction against abrasive surfaces during transit.

- Sustained sunlight and UV contact may erode the outer PVC coating progressively.

PVC Steel Wire Hose

PVC steel wire hose incorporates a PVC core tube, an integrated steel wire spiral, and a sleek PVC sheath. The helical steel wire imparts structural reinforcement, pliability, and rigidity. Primary uses occur in construction, mining, and bulk material conveyance.

Pros

- PVC steel wire hose functions effectively in vacuum configurations, boasting strong suction performance for tasks like dewatering or solids retrieval.

- Its clear, hygienic design permits direct observation of media flow and obstruction identification.

- It employs non-toxic materials.

- Calibration markings are inscribed along the hose length.

- It manages high-pressure scenarios, ensuring consistent media transport in challenging environments.

Cons

- Improper manipulation risks kinking, which impedes fluid passage.

- It falls short in extreme temperature operations.

Reinforced PVC Hose

These PVC hoses feature a PVC liner tube, layered reinforcements, and an encasing of PVC or synthetic rubber. The external layer safeguards against frictional wear, atmospheric exposure, and mechanical harm. Reinforced PVC hose aligns with conveyance of pressurized or aggressive gases and liquids. It gains prominence in mechanical systems, coal extraction, oilfields, and chemical sectors.

Pros

- Reinforced PVC hose performs optimally under high-pressure conditions.

- Its robust build guarantees prolonged operational duration.

- PVC-reinforced hoses accommodate chemical treatment processes.

Cons

- It lacks viability for elevated temperature uses.

- Compatibility issues arise with specific chemicals.

PVC Suction Hose

A PVC suction hose is engineered to endure vacuum pressures. It includes a PVC interior tube, stiff spiral reinforcement, and a PVC or synthetic rubber exterior. The spiral element upholds form stability, averting collapse during vacuum or aspiration phases. PVC suction hose prevails in wastewater treatment, adeptly managing sewage, sludge, and solid-laden fluids.

PVC suction hose extends to agricultural and maritime functions, supporting irrigation, pumping, and drainage setups. Maritime roles encompass bilge evacuation, fluid relocation, and slurry management.

Pros

- PVC suction hose excels in vacuum and suction environments.

- The firm spiral reinforcement delivers mechanical fortitude, inhibiting deformation and preserving system reliability.

- It combines flexibility, selective chemical resistance, and economic value.

Cons

- Blockages may occur when conveying fluids with substantial particulates or residues.

- It does not support high-pressure operations.

- High-temperature settings are incompatible.

PVC Garden Hose

These hoses suit domestic and commercial environments. Deployments cover horticulture, exterior sanitation, and routine water delivery. A PVC Garden Hose comprises a PVC core tube, polyester or nylon reinforcement, and synthetic rubber sheathing.

PVC Garden Hose supports plant, turf, and landscape irrigation in both settings. In cleaning tasks, it aids vehicle, deck, pathway, and fixture rinsing. Additionally, PVC Garden Hoses handle water provisioning, such as replenishing pools, reservoirs, or vessels.

Pros

- PVC Garden Hose offers reduced mass and pliability, streamlining transport, operation, and storage.

- It includes connectors for seamless integration with sprinklers or irrigation tools.

- Economic advantages are prominent.

- As a PVC Flexible Water Hose, it demonstrates adaptability and weather durability.

Cons

- Pressure tolerances are inferior to other PVC Hoses, precluding high-pressure uses.

- Kinking propensity hampers flow, necessitating physical correction.

Conclusion

This article has examined the domain of PVC Hoses and their classifications. Insights into composition, core attributes, advantages, and drawbacks of PVC Hoses were provided. PVC hose outperforms alternatives in targeted scenarios. Nonetheless, it remains unsuitable for elevated temperatures, where rubber hoses are preferable.

Selecting a PVC hose demands evaluation of application-specific parameters. Critical considerations encompass pressure ratings, thermal limits, and ambient exposures. Engagement with industry experts or hose authorities can yield tailored guidance for optimal PVC Hose procurement.